Just like how our left hemisphere and right hemisphere work together, or a better example -- when two musicians performing a duet --- we want to see what happens when we are coordinating actions with others.

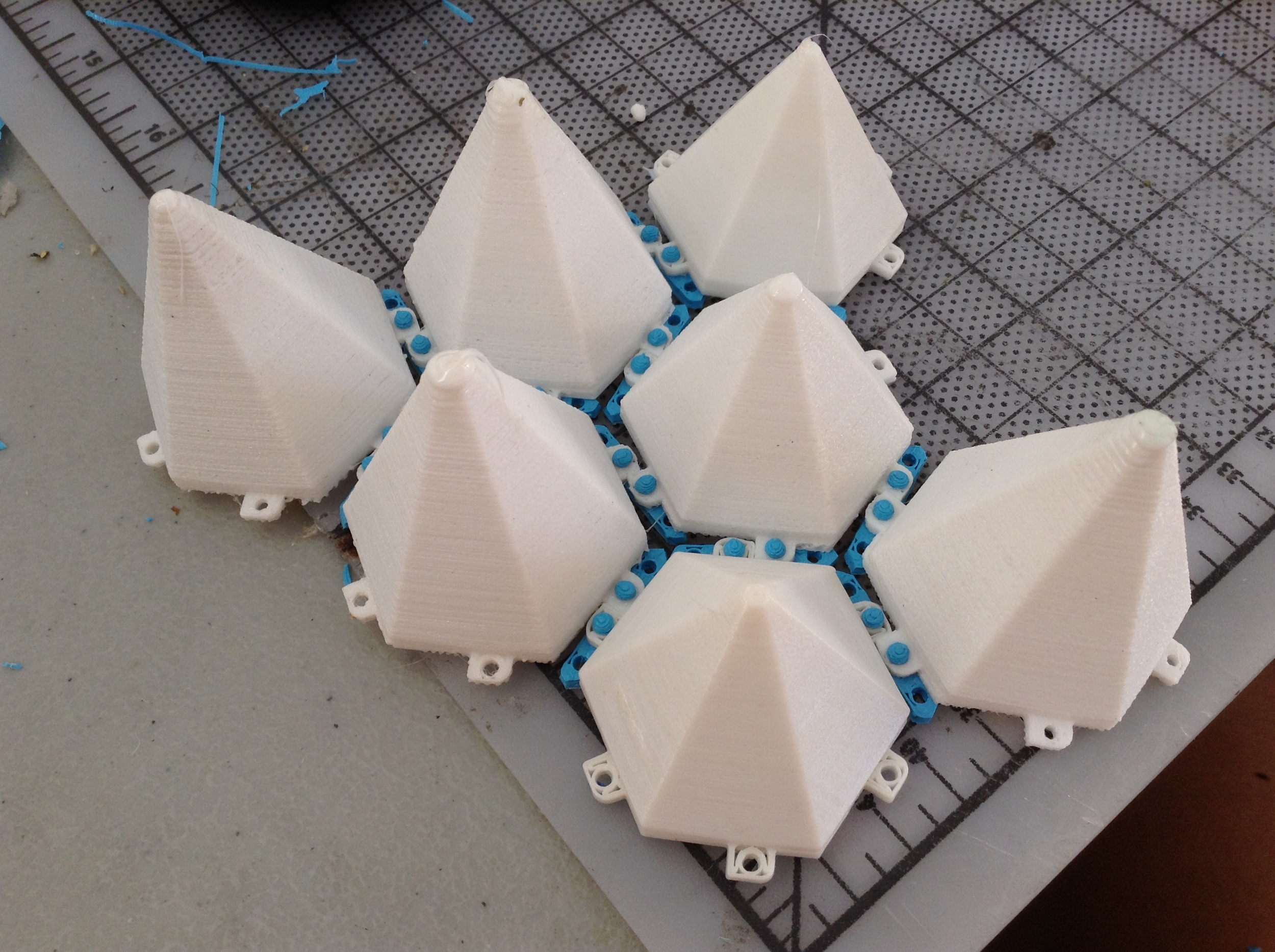

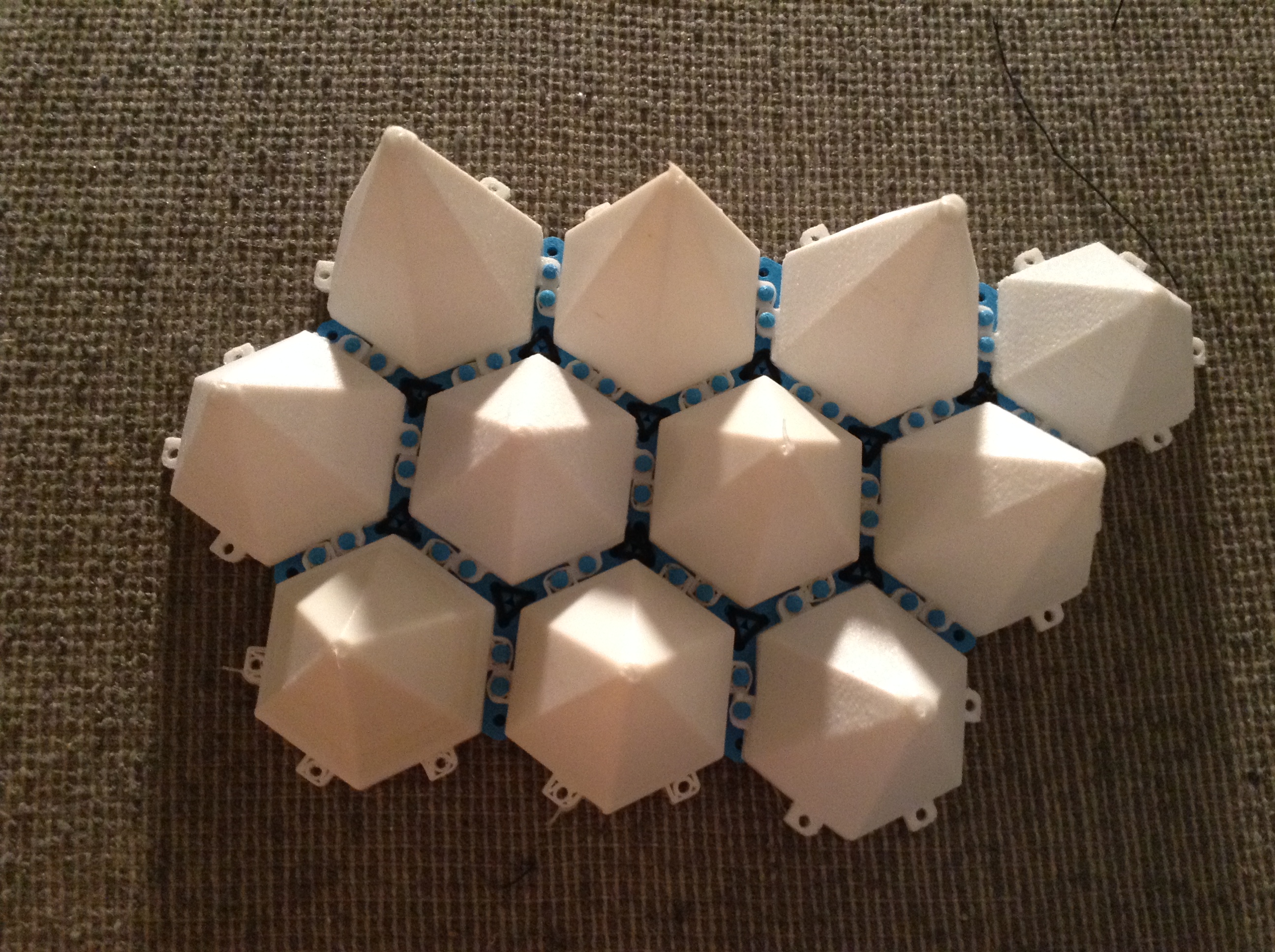

This project takes small forces from the hands of participants and scales them up, creating a stage where air, wind, fog, vibration can affect a crowd. The project features wearable devices with embedded sensors which are worn by users who then use their muscles and body gestures to make the space "playable". The goal is a supple, playful system that gives new powers to the wearer. At the same time, small and large flying objects in the space are being used as a form of visual aid to suggest that the "super power" or energy from the wearer are present -- forces which can be felt on the stage in form of a dramatic shake or gust of wind also made visual through unique forms that dance and animate.

Some prototype testing can be viewed here: