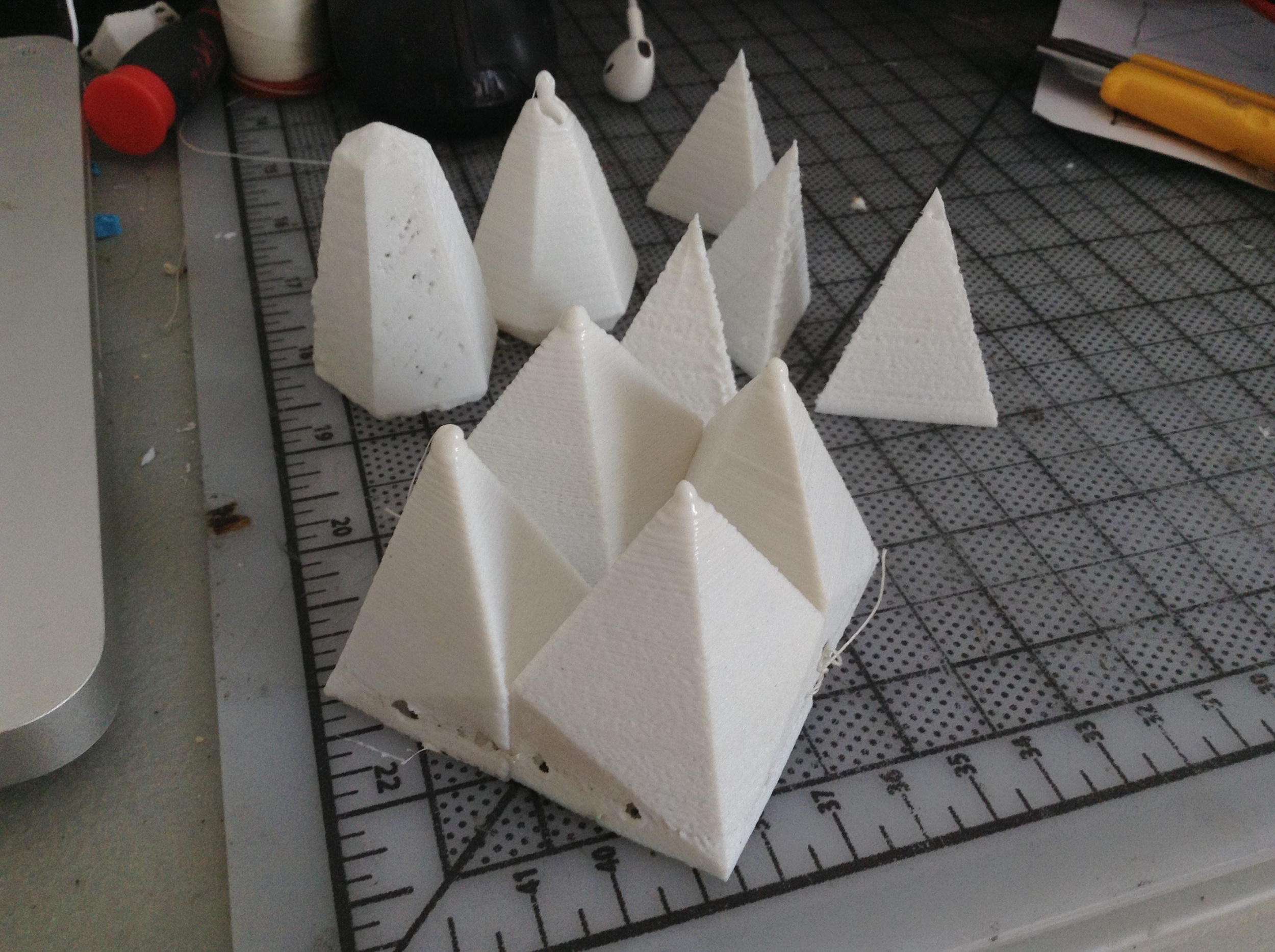

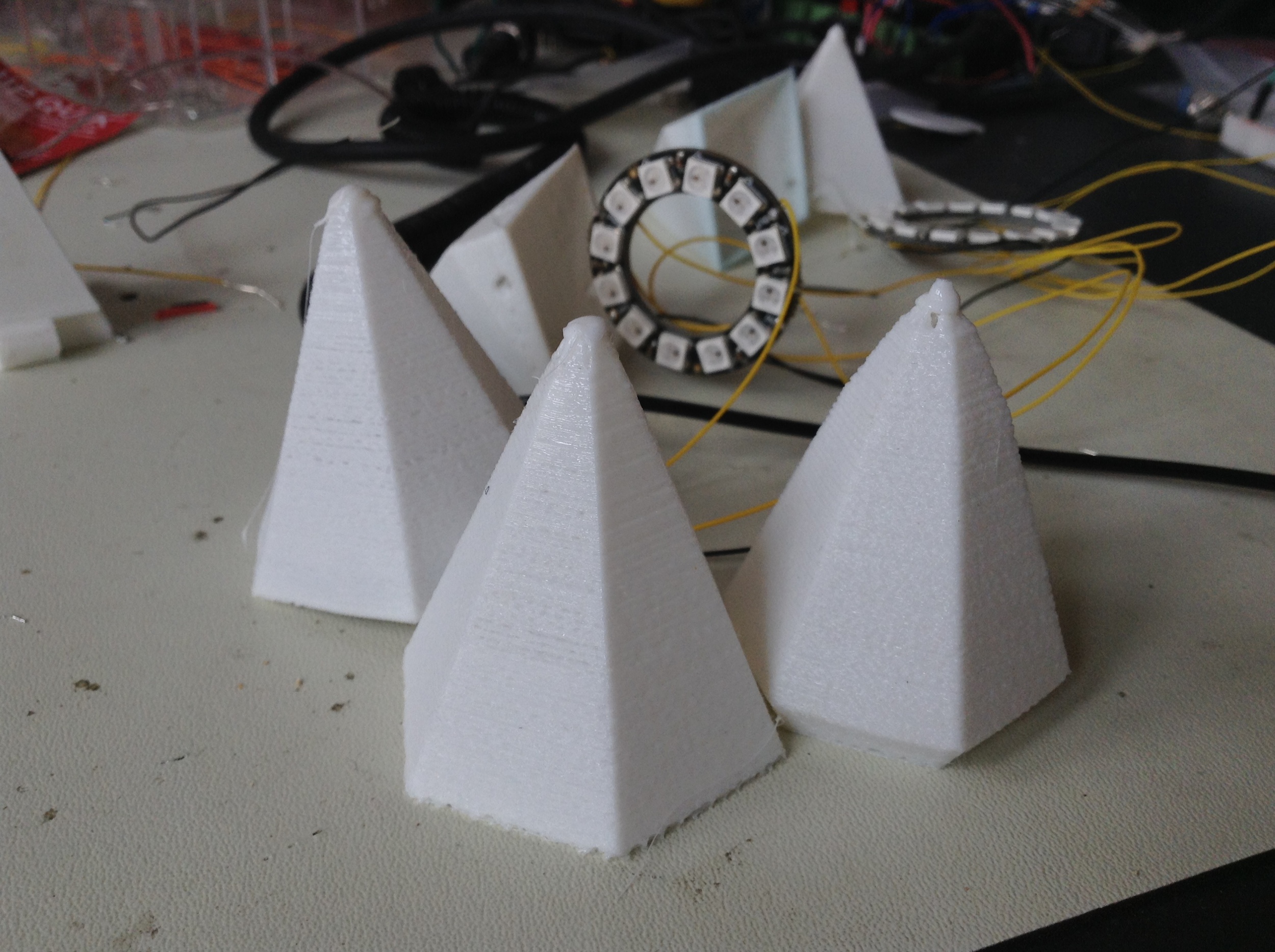

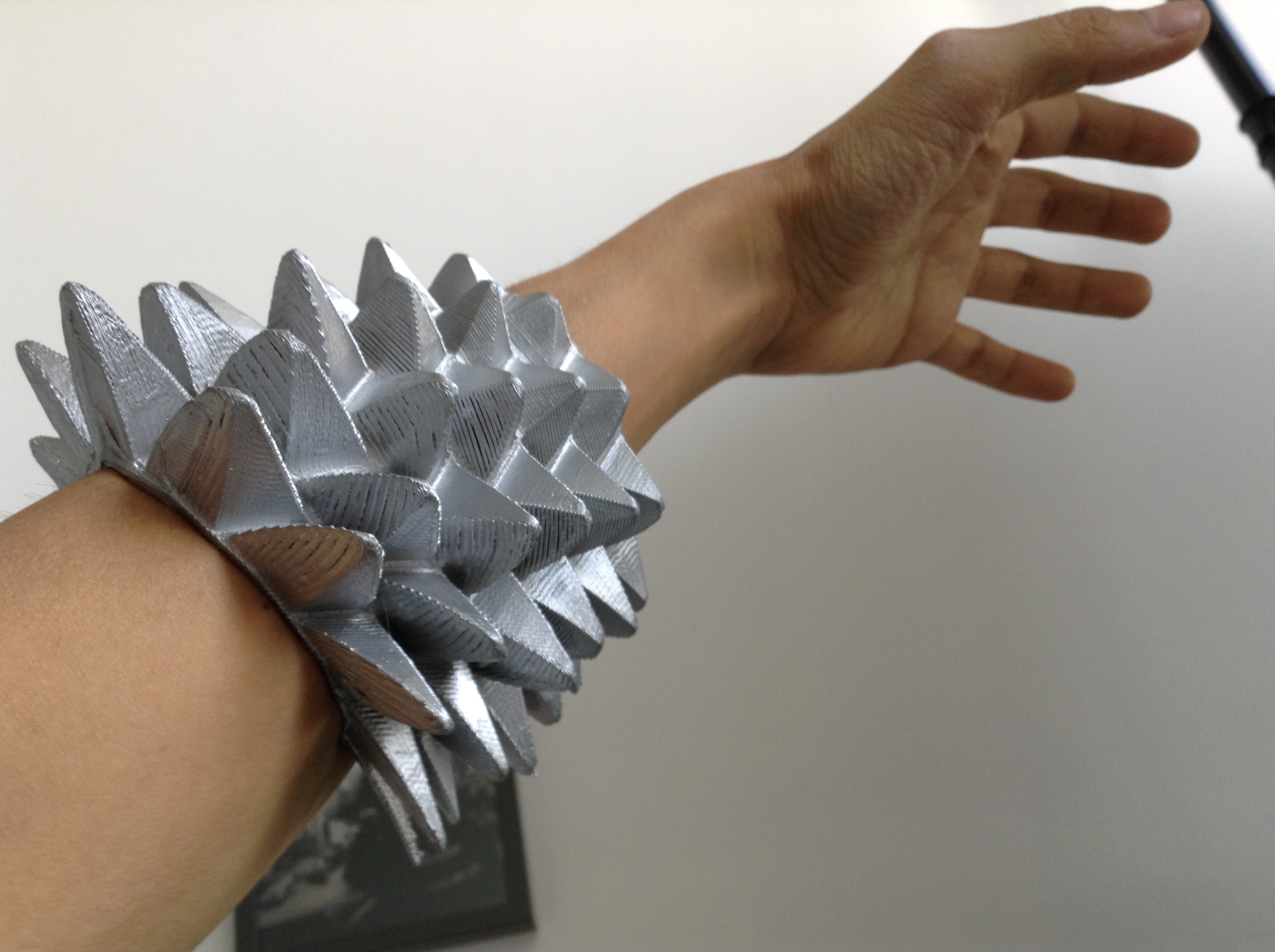

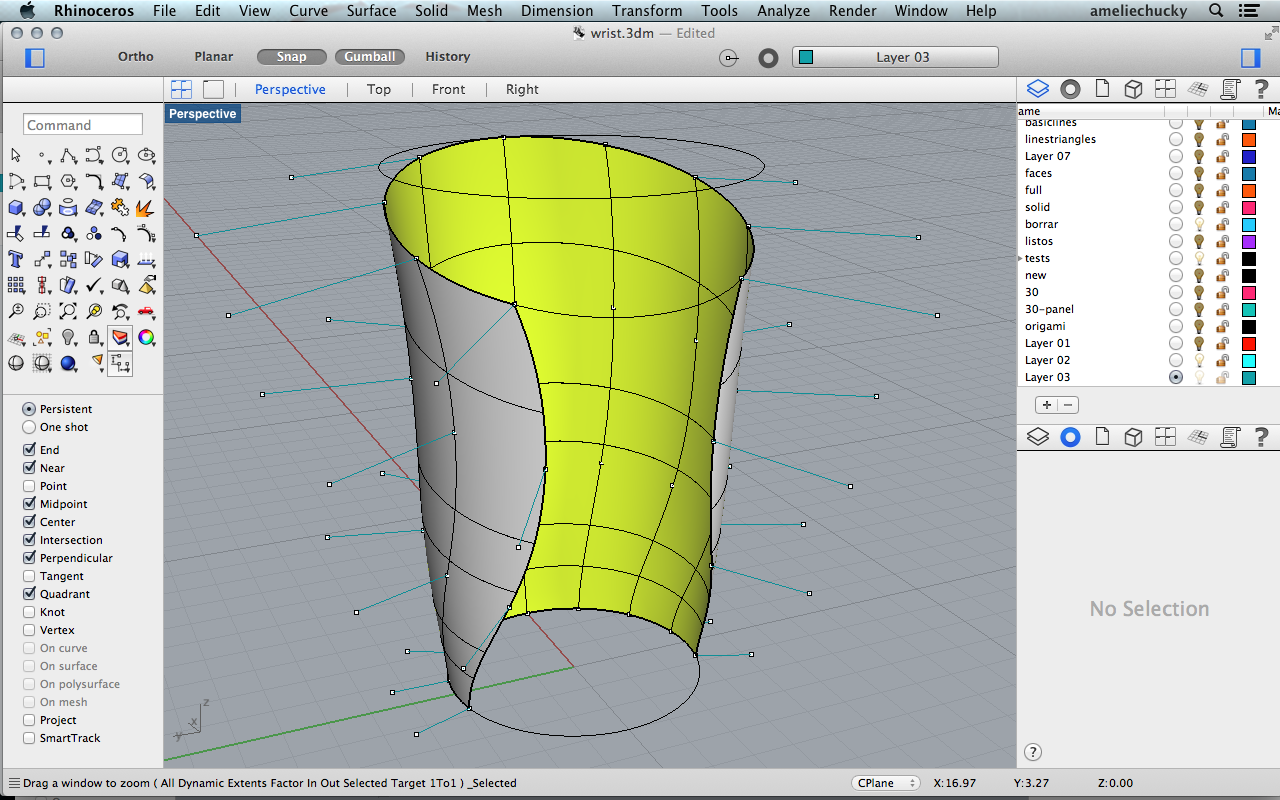

This research shows different shapes for spikes that we can sew to the fabric to cover the arm band with the sensors and the electronics. We started to work in a modular way to get the look we are looking for. Also we are working with soft materials to make it safe for kids.

Some materials include leather (grey) and ninja flex printed in our new 3D printer (Ultimaker2).

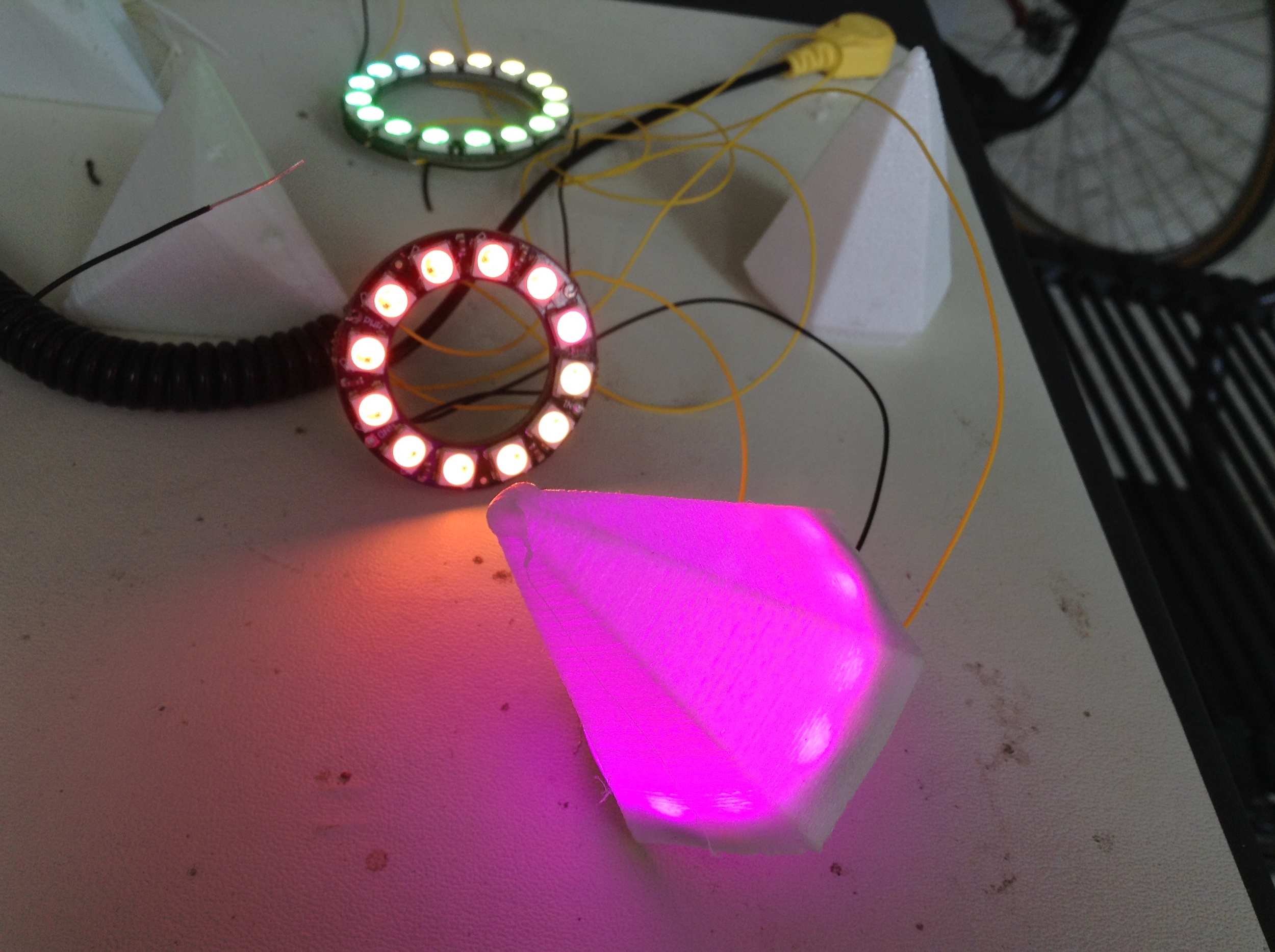

The final shape allows us to include LEDs inside this spikes with a great look. This material is great spreading the light, you can see the images bellow.

more iterations.

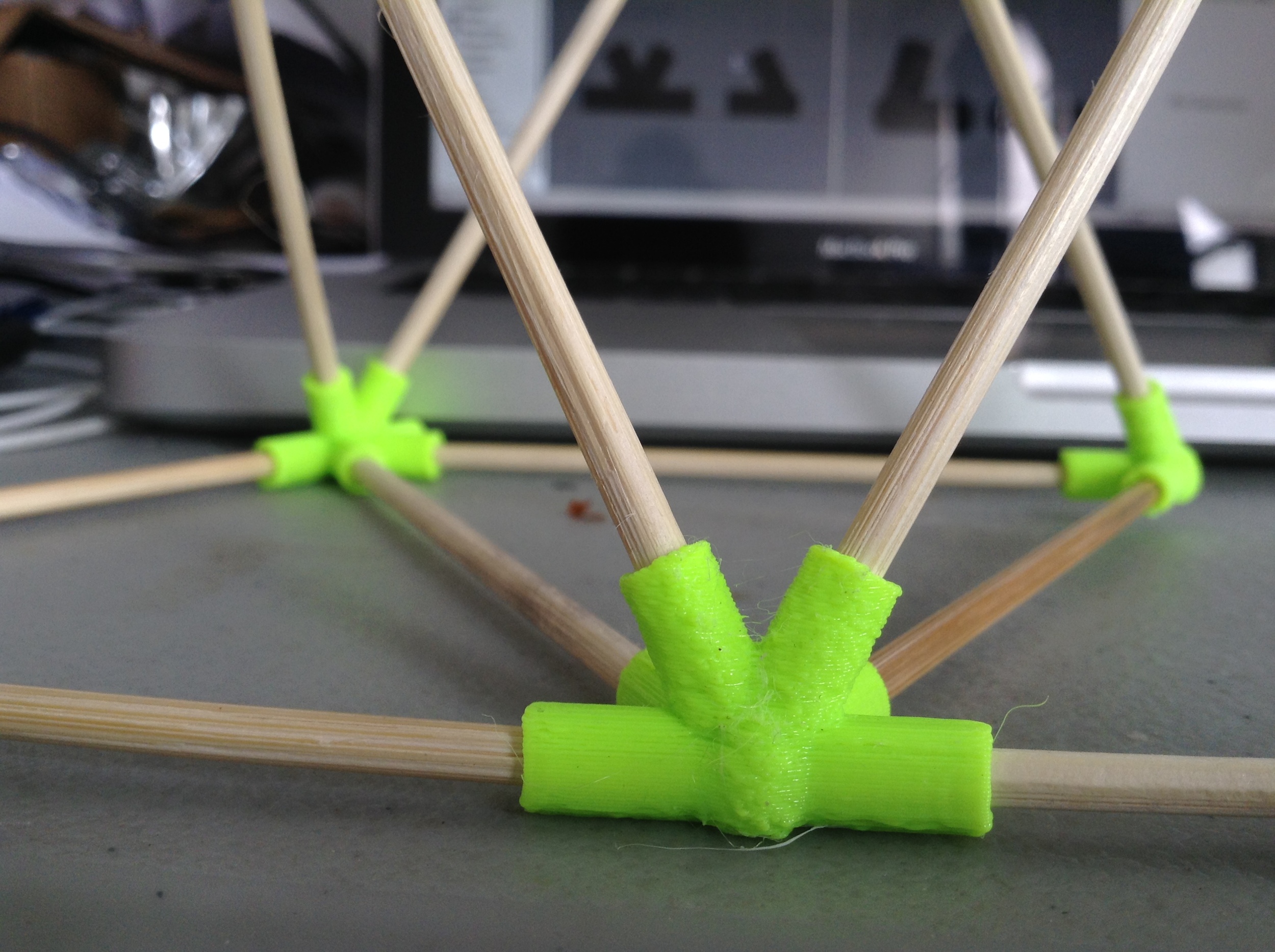

Following the modular line, we are working in joints that can be easily attached and sewn to fabric. 3D printing another piece on PLA (blue) seems like it's working good.

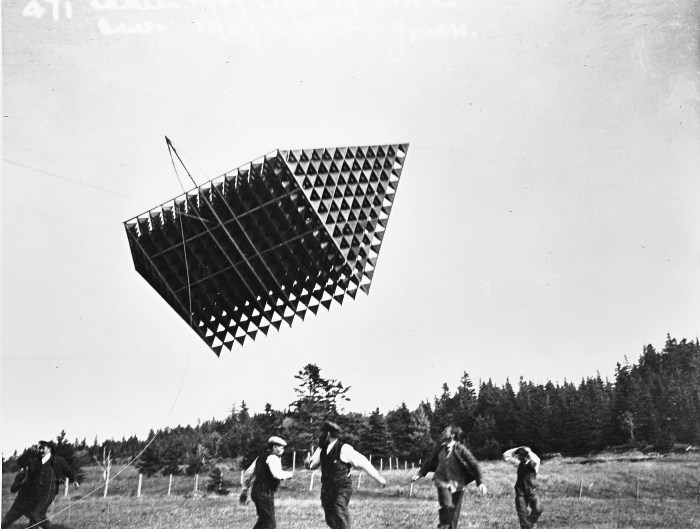

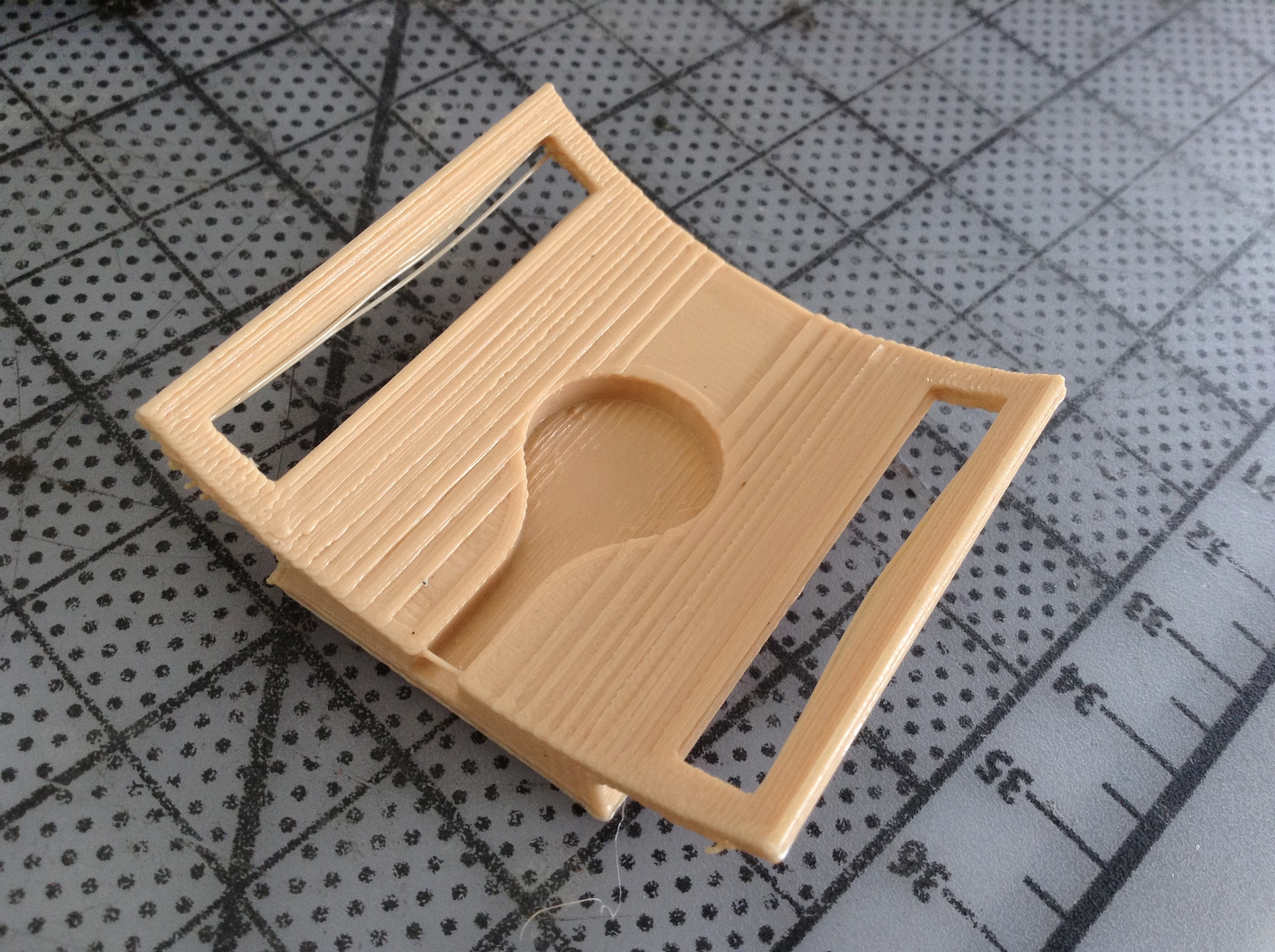

Last version, not printed yet, includes holes to sew the PLA piece to the fabric, see last image bellow.